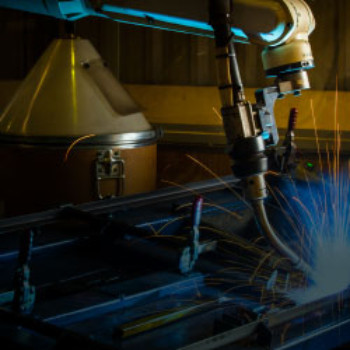

Safety and control for process and OEM equipment

United Electric Controls (UE) manufactures standard and custom designed solutions for safety, alarm, and emergency shutdown (ESD) functions that reduce complexity, simplify installation and achieve regulatory compliance. UE is focused on protecting people, equipment, processes, and the environment and its proven solutions include:

Our Expertise

Explore our Company

Learn about United Electric Controls and how we protect industry with the highest quality safety solutions, with over 90 years of experience.

Vanguard WirelessHART Gas Detector

See the cost benefit of a Wireless vs. Wired Gas Detection System, monitoring toxic and combustible gases without the need for costly and fixed wiring.

Excela Electronic Switch Animation

Explore the benefits of our new 2-Wire Electronic Switch. Upgrade your mechanical switch with ease of installation and affordability.